Other ProductsSERVICE&PRODUCTS

Pressure Reducing Valve (⇒Catalog PDF)

In pneumatic tools and associated systems, a critical component is the

pressure reducing valve, also known as a constant pressure valve. In professional

environments, maintaining consistent air pressure from the piping system

is essential, as adjustments to this pressure can significantly influence

the performance of pneumatic tools. This is particularly relevant in large-scale

industrial settings, where pressure losses due to extensive piping networks

are common. Pressure reducing valves are widely employed in various pneumatic

tools such as impact wrenches, spray guns, and nail guns to mitigate excessive

pressure and ensure optimal operating conditions. Notably, DAISEN pressure

reducing valves feature a dial-type design, enabling precise and user-friendly

pressure adjustments.

In pneumatic tools and associated systems, a critical component is the

pressure reducing valve, also known as a constant pressure valve. In professional

environments, maintaining consistent air pressure from the piping system

is essential, as adjustments to this pressure can significantly influence

the performance of pneumatic tools. This is particularly relevant in large-scale

industrial settings, where pressure losses due to extensive piping networks

are common. Pressure reducing valves are widely employed in various pneumatic

tools such as impact wrenches, spray guns, and nail guns to mitigate excessive

pressure and ensure optimal operating conditions. Notably, DAISEN pressure

reducing valves feature a dial-type design, enabling precise and user-friendly

pressure adjustments.

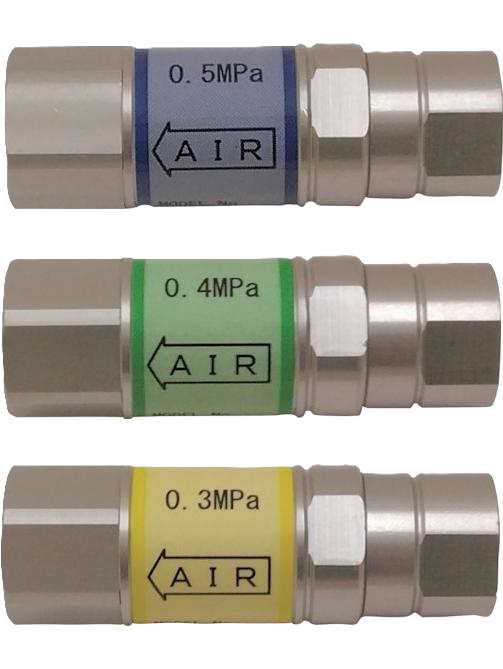

Constant Pressure Valve (⇒Catalog PDF)

A constant pressure valve is engineered to ensure a stable output pressure,

irrespective of variations in the input pressure. While it is sometimes

classified as a subtype of pressure reducing valve, its distinguishing

feature lies in its specialization in "pressure stability.

A constant pressure valve is engineered to ensure a stable output pressure,

irrespective of variations in the input pressure. While it is sometimes

classified as a subtype of pressure reducing valve, its distinguishing

feature lies in its specialization in "pressure stability.

"This makes it particularly valuable in precision applications where

pressure fluctuations are unacceptable, such as air pressure regulation

in semiconductor manufacturing equipment and medical devices. In the context

of pneumatic tools, it is utilized to reduce inconsistencies in spray gun

paint application or to provide the stability necessary for sustained,

continuous operation. DAISEN offers a range of 16 constant pressure valve

variants, each tailored with distinct set pressures and connection thread

types to meet diverse operational requirements.

Releif Valve (⇒Catalog PDF)

An air pressure relief valve is a safety device that automatically releases

excess pressure when the pressure in a pneumatic system exceeds a set value.

This valve prevents overpressure in the system and plays a role in avoiding

damage to equipment and piping and accidents.

An air pressure relief valve is a safety device that automatically releases

excess pressure when the pressure in a pneumatic system exceeds a set value.

This valve prevents overpressure in the system and plays a role in avoiding

damage to equipment and piping and accidents.

Manifold (⇒Catalog PDF)

Multiple air outlets can be seamlessly integrated into a single pipe, offering

flexibility with a choice of either two to four branches to suit the specific

requirements of your task. Featuring a rotary function, the air outlet

allows for full 360-degree rotation, ensuring optimal adaptability and

precision in any professional application.

Multiple air outlets can be seamlessly integrated into a single pipe, offering

flexibility with a choice of either two to four branches to suit the specific

requirements of your task. Featuring a rotary function, the air outlet

allows for full 360-degree rotation, ensuring optimal adaptability and

precision in any professional application.